Drive operational excellence with Supply Chain Execution & Manufacturing Operations Management

Due to increasing difficulty and unpredictability, supply chain organizations have to modify their technology investments to make them adjust to their requirements for resilience, speed, and smart operations. Supply chain execution and manufacturing operations management are two distinct but closely related areas of business operations.

Supply chain execution refers to the management and coordination of all activities involved in the movement of goods from raw materials to the end consumer. This includes activities such as procurement, logistics, warehousing, and distribution.

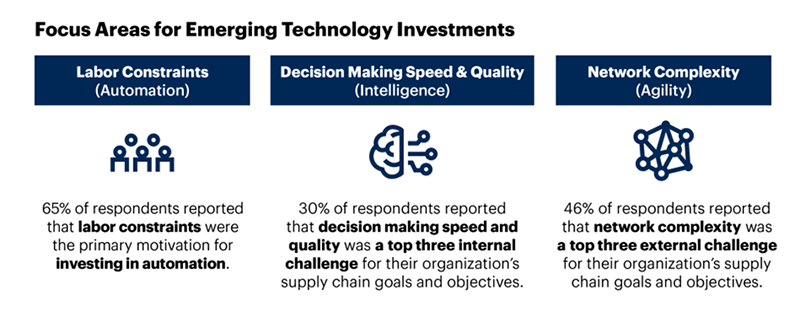

According to the Gartner- Only 1% of supply chain organizations say they have no plans to invest in emerging technologies over the next five years while the vast majority of companies cite multiple reasons for doing so.

Manufacturing operations management, on the other hand, refers to the management of the processes and resources used to produce goods. This includes activities such as production planning, scheduling, and control, as well as the management of the facilities, equipment, and personnel used in the manufacturing process.

As businesses become more global and supply chains become more complex, there is an increasing need for these two areas to converge. The convergence helps to ensure that goods are produced and delivered in a timely and efficient manner, while also reducing costs and improving overall supply chain performance. It also allows for better visibility and control over the entire production process, from raw materials to finished goods, which can help companies respond more quickly to changes in customer demand or market conditions.

To accelerate Supply Chain Execution convergence with manufacturing operations, operations leaders should consider the following steps:

Establish clear goals and objectives: Define what you want to achieve through the convergence of supply chain execution and manufacturing operations. This will help to ensure that all efforts are aligned towards a common goal.

Assess current processes: Understand how your current supply chain execution and manufacturing operations processes work, and identify areas for improvement. This will help to determine where changes need to be made to support the convergence of the two areas.

Implement technology solutions: Invest in technology that can help to improve the visibility and coordination of supply chain execution and manufacturing operations. This can include enterprise resource planning (ERP) systems, manufacturing execution systems (MES), and supply chain management software.

Foster collaboration: Encourage collaboration and communication between supply chain execution and manufacturing operations teams. This can help to ensure that both teams are working towards the same goals and that information is shared in a timely and efficient manner.

Continuously monitor and evaluate: Monitor the progress of the convergence and evaluate the effectiveness of the changes that have been made. This will help to identify any issues and make any necessary adjustments to ensure that the goals and objectives are met.

Develop a culture of continuous improvement: Encourage a culture of continuous improvement and experimentation within the organization to ensure that the company is always looking for ways to optimize the performance of the supply chain and manufacturing operations.

Through 2026, less than 20% of supply chain management (SCM) suite vendors will have adopted a composable go-to-market approach, although some will have adopted a microservices architecture- Says Gartner

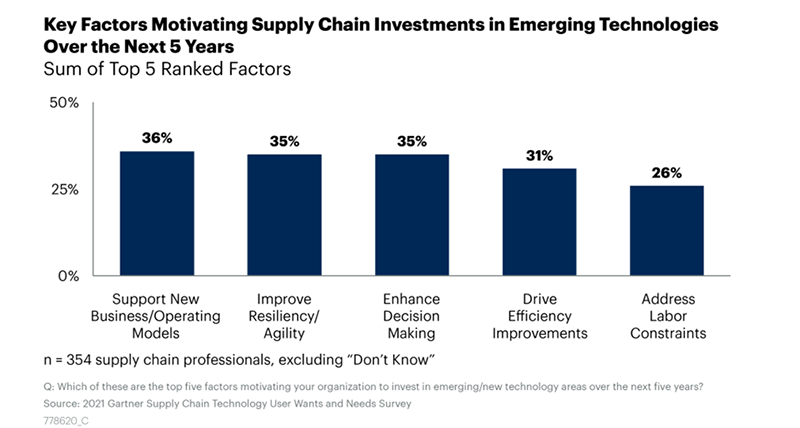

Key Factors Motivating Supply Chain Investments in Emerging Technologies Over the Next 5 Years

1. Support new business: Emerging technologies can enable new business models and revenue streams, such as on-demand manufacturing and digital twinning. Having the right technology in place allows businesses to quickly develop new products and services which can be used to target new markets. Additionally, businesses can use the data generated from these technologies to create better customer experiences and improve customer loyalty.

2. Improve resiliency: Technologies such as IoT, machine learning, and blockchain can improve supply chain visibility, enabling companies to more quickly respond to disruptions and better manage risks.

3. Enhance decision making: By leveraging data analytics and predictive algorithms, companies can quickly and accurately identify the most profitable supply chain strategies. Furthermore, these technologies can be used to automate and streamline complex processes, allowing companies to reduce the time and cost associated with decision making.

4. Drive efficiency improvements: By leveraging latest technologies, businesses can gain a better understanding of their operations, identify and address disruptions, and optimize their supply chain for greater efficiency. This can help businesses remain competitive and improve their bottom line.

5. Address labor constraints: Automation technologies such as robots, drones, and autonomous vehicles can help companies improve efficiency, reduce costs, and address labor constraints. These technologies can be used for a wide range of applications, including warehouse management, transportation, and packaging.

The end of silos in the supply chain and process reliability due to Supply Chain Execution and Manufacturing Operations Management Convergence

By 2026, over 65% of short-term decisions within supply chain planning (SCP) will be automated or autonomous.

Supply Chain Execution (SCE) and Manufacturing Operations Management (MOM) convergence can lead to the end of silos in the supply chain by providing a unified view of all processes and enabling better communication and collaboration between different departments and partners. This can result in increased efficiency and agility to help organizations respond more quickly to changes in demand or disruptions in the supply chain. By having a comprehensive view of the supply chain, organizations can identify potential bottlenecks and vulnerabilities, and take proactive measures to mitigate them.